KREOSOTE

AMERICAN BUILT FOLKLORE BOOTS

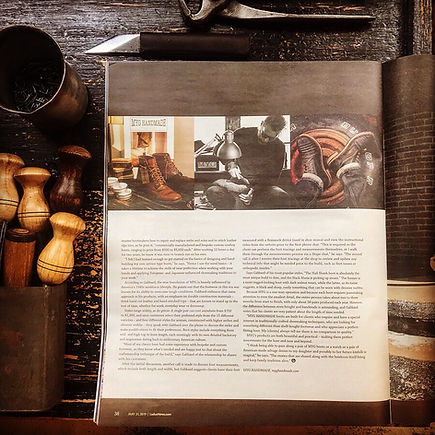

JD Gabbard is a One man operation that single handedly bench-builds a Limited number of originally designed (MTM Kustom) boots each year using Traditional Cordwainer European /American Shoemaking methods.

There isn't an Apprenticeship program set up or any work-shop Assistants here at KREOSOTE, the highest level of quality is managed throughout the process as I build each boot to the Clients MTM specifications, guaranteeing the Client receives the most uniquely built functioning work of Labor and attention to detail that I can provided.

With great admiration, I will continue to support American Tanneries and the American made supply materials that are used to build KREOSOTE boots.

It is the tenacity of these Companies and Workers that continue to define the foundation of my work.

KREOSOTE 2025.